Past Elementary Concepts: Advanced Applications of Continuous Reduction Within Volume Conveyors

In the field of manufacturing processing, precision and efficiency are paramount. Loss In Weight Feeders have become as a vital approach for organizations looking to optimize their material delivery systems. These advanced devices not only enhance accuracy in product handling but also encourage smooth compatibility with various bulk handling equipment such as Bulk Bag Unloaders and Bulk Container Dischargers. As industries evolve, so does the complexity of their operations, demanding sophisticated applications that go past the basics.

Understanding the advanced capabilities of Continuous Loss In Weight Feeders can enhance output capabilities. From improving the consistency of mixtures to ensuring the standard of end products, these systems provide unmatched control over material feeding rates. By exploring their complex designs and versatility, we will investigate how these feeders can transform not only feeding mechanisms but also the overall efficiency of bulk handling processes in varied production settings.

Overview to Loss-in-Weight Feeders

Feeders that operate on a continuous loss in weight principle are advanced systems designed for exact material handling and feeding in various industrial applications. By constantly measuring the weight of the material being supplied, these feeders ensure consistent product delivery, which is vital for maintaining quality in manufacturing processes. The ability to provide immediate feedback and exact control allows these systems to optimize production efficiency and decrease waste.

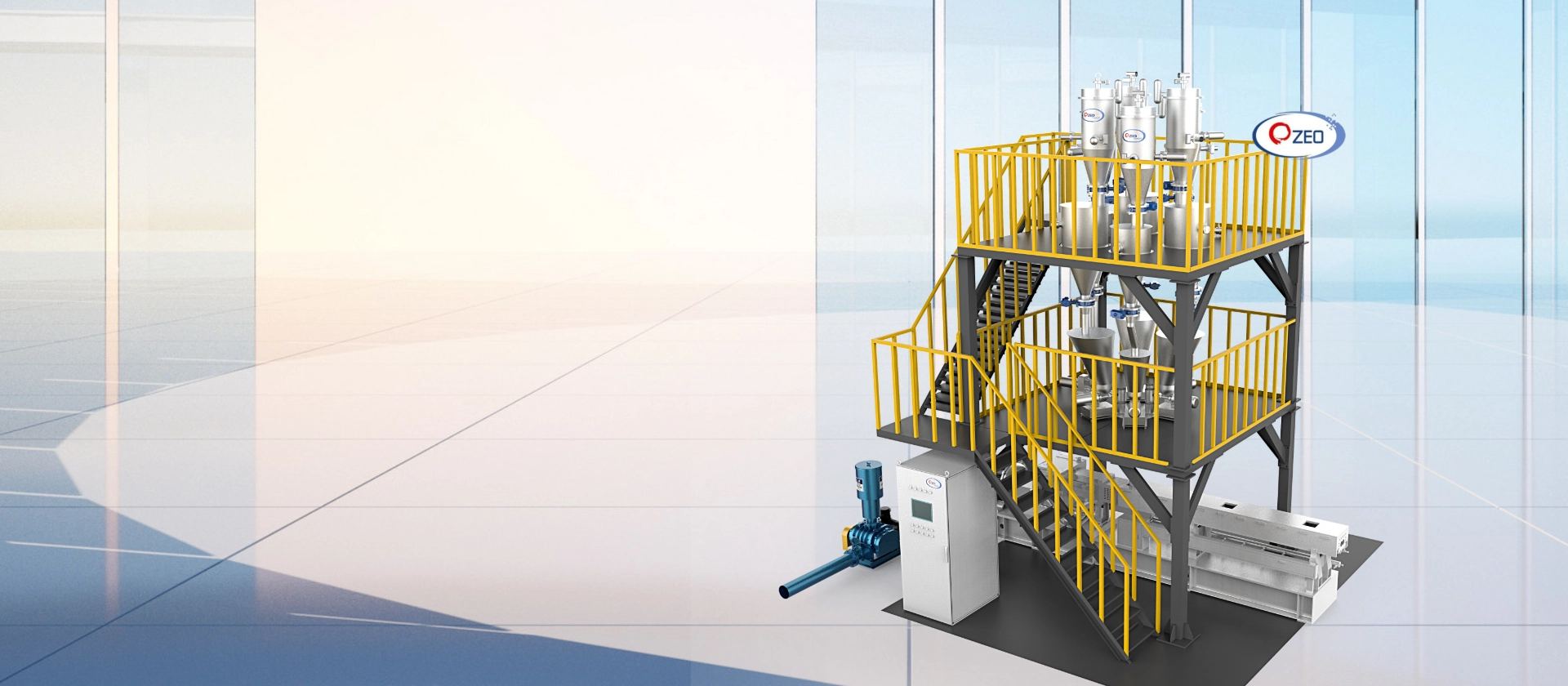

The operation of continuous loss in weight feeders relies on a combination of high-tech technology and engineering principles. They usually consist of a bin to hold the bulk material, a conveyor, and sensitive load cells to measure the weight. These parts work collaboratively to provide a continuous flow of material while continuously adjusting the feed rate to match the desired output. This dynamic adjustment enhances the reliability of the feeding system within various materials and processes, from basic bulk powders to complex mixtures.

In conjunction with other systems like bulk bag unloaders and bulk bag dischargers, continuous loss in weight feeders provide a holistic solution for bulk material handling. These feeders can enhance operations, minimize manual labor, and minimize the risk of contamination. As industries evolve and demand increased efficiency, understanding the advanced applications of continuous loss in weight feeders becomes necessary for companies looking to improve their production capabilities.

Improving Feeding System’s Efficiency

To boost the effectiveness of constantly losses in weight feeders, it is crucial to focus on the adjustment and maintenance of the feeder. Consistent adjustment ensures that the feeder reliably delivers the correct amount of material, reducing variations that can affect the overall process. Maintenance, comprising regular checks on parts such as load cells and control systems, helps prevent stoppages and guarantees reliable operation. By establishing a structured routine for calibration and maintenance, facilities can noticeably improve the material handling system’s performance and longevity.

Incorporating advanced monitoring technologies can also play a crucial role in optimizing feed system performance. Combining of real-time data analytics allows operators to observe the performance of the feeder continuously, identifying trends and potential issues before they arise. This proactive approach facilitates swift adjustments to be made, maintaining optimal feed rates and material consistency. Establishing a feedback loop from the feeder to the control system can also enhance responsiveness, resulting in a more efficient feeding process.

In conclusion, integrating the constant loss in weight feeder with appropriate bulk bag unloaders and bulk bag dischargers is crucial for streamlined operations. The layout and configuration of these components should match the feeder to limit material degradation and ensure efficient transitions between feeding stages. Such alignment not only protects material integrity but also enhances the total capacity of the material handling system. By carefully combining these components, companies can maximize productivity and efficiency in their material handling processes.

Integration with Bulk Material Unloaders

Unifying continuous loss in weight feeders with bulk bag unloaders brings considerable advantages to the overall material handling system. Bulk bag unloaders allow the smooth transfer of bulk materials from bags into the feeding system. By integrating these technologies, operators can enhance workflow efficiency, reduce material spillage, and improve accuracy in material discharge. This synergy enables for seamless transitions between bulk bag discharging and continuous feeding.

The continuous loss in weight feeders works on a principle of real-time weight measurement, which assists in precise dosing of materials as they are unloaded from bulk bags. https://www.awesomeextrusion.com/ confirms that the material flow is continuously tracked and adjusted, lessening overloading or underloading situations. As bulk material is removed from the bags, the feeder responds instantly to maintain consistent delivery rates, thus enhancing the production process and reducing downtime.

Additionally, this combination enhances safety and operational reliability. With automated controls in place, operators experience less manual handling of bulk materials. This minimizes the risk of spills and accidental exposure to likely hazardous materials. The integration of bulk bag unloaders and continuous loss in weight feeders not only optimizes operations but also encourages a cleaner and safer working environment for staff, ultimately leading to improved productivity and reduced operational costs.

Enhancing Productivity through Large Container Dischargers

Bulk container dischargers play a key part in the efficiency of constant loss in weight feeder mechanisms. Such devices are constructed to enhance the unloading procedure of bulk materials, ensuring a constant and steady movement into the feeding system. Through connecting bulk bag unloading systems to the feeding system, companies can obtain a significantly consistent material supply, minimizing stoppages and enhancing total output.

When utilizing bulk bag unloading systems, staff enjoy from improved material management. These systems typically feature advanced designs that diminish particulate emissions and improve protection during the offloading procedure. With automated functions, including shaking and adjustable rate settings, they guarantee that substances are uniformly supplied into the continuous drop in weight feeding system, which is essential for ensuring precision and reducing output scrap.

Additionally, the synergy between bulk bag dischargers and loss in weight feeders enables for better monitoring and control of material consumption. This combination helps companies streamline their processes, leading to financial savings and better output quality. With adopting such innovative technologies, businesses can greatly improve their functional ability and fulfill the requirements of flexible manufacturing environments.